We offer specialized silicone extrusion molding services, or producing continuous silicone profiles, tubes, and seals with exceptional consistency and durability. Our advanced extrusion capabilities make it possible to manufacture parts that are flexible, resilient, and tailored to your unique application needs.

- Greate Technology

- Certified Engineers

- Delivery Ontime

- Best Branding

Our Work Process

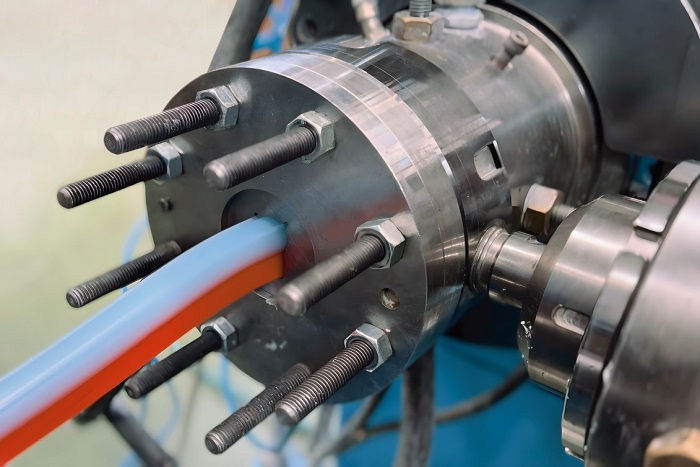

The process starts with a detailed consultation to understand your specifications, including shape, size, and material requirements. High-quality silicone is then precisely extruded through custom dies, creating continuous products with exact profiles. Each product undergoes rigorous quality checks to confirm strength, durability, and compliance with industry standards.

Finally, we cut, finish, and package the products to your exact requirements, ensuring ready-to-use solutions delivered on time.

Applications

Silicone extrusion molding is ideal for creating products that require continuous lengths and uniform profiles. We manufacture silicone tubes, cords, gaskets, seals, and custom profiles used in industries such as healthcare, automotive, electronics, and consumer goods. Our extruded silicone products are non-toxic, heat- and chemical-resistant, and perfectly suited for applications that demand safety and long-term reliability.

We also produce silicone-based items for children, such as feeding accessories and protective edges, ensuring both functionality and safety.